ABTER – Top Quality Steels !

our services

Pipe & Fittings Cutting :

Machining services:

Welding:

Custom Bending Pipe :

Inspection and Documentation

C. Welds including welder and filler material certifications D. Electropolishing or Passivation Certification E. Material Certificates

Threading & Custom Fabrications

Abter Products

Stainless Steel Pipes

Pre-insulated pipes

COMPANY

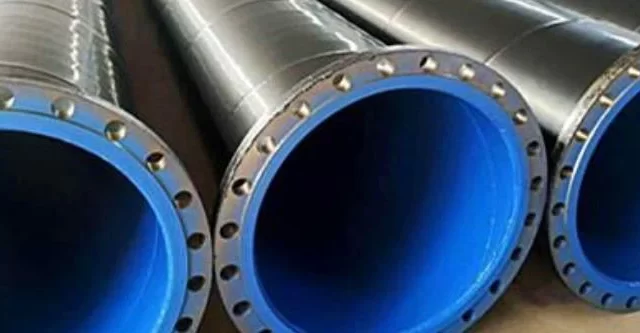

2PE/3PE Anti-corrosion Coated Pipe

Alloy steel pipes

Carbon & Alloy steel pipe fittings

ABTER STEEL

“Over the past 30 years, Abter steel company has been committed to the piping system industry.“

latest news & events

The study of corrosion and its inhibition in galvanized steel pipes within water supply systems is a critical area of infrastructure science, merging electrochemistry, material engineering, and public health concerns. Dealing with this topic requires dissecting the fundamental mechanisms of zinc and iron degradation, and then exploring the chemical and physical strategies used to mitigate these effects and prolong system life.

Hard Polyurethane Foam insulation, integrated with a robust anti-corrosion layer and an HDPE outer jacket, remains the preeminent technology for thermally efficient buried steel pipelines. Its success hinges on a deep understanding of the material science, a rigorously controlled manufacturing process, and meticulous attention to installation and field jointing details.

JIS G 3445 STKM seamless carbon steel pipes, ranging from STKM11A to STKM20A, provide versatile, cost-effective solutions for mechanical and structural applications, with carbon content (0.12–0.25%) tailored for formability and strength. Seamless manufacturing ensures defect-free performance, making them ideal for automotive (e.g., shock absorbers), machinery (e.g., cylinders), construction (e.g., fluid lines), and feed additive production (e.g., heat exchangers for chicken liver powder and choline chloride). Grades like STKM12C and STKM13A offer a 10–15% longer lifespan in mild corrosive environments compared to welded pipes. The global seamless pipe market, projected to grow at a CAGR of 4.5% to USD 25 billion by 2032, reflects strong demand for these materials. Compared to alloy steels like Incoloy 825 or stainless steel A312 TP316Ti, STKM pipes are more affordable but limited to less aggressive conditions. Their compliance with JIS G 3445, ASTM A519, and EN 10204 ensures reliability through rigorous testing. As industries prioritize efficiency, STKM pipes remain a cornerstone for cost-effective engineering solutions. For inquiries or customized solutions, please contact us at [insert contact details]. These pipes continue to support high-performance, reliable systems across diverse applications.

JIS G 3445 STKM seamless carbon steel pipes (STKM11A to STKM20A) offer a cost-effective, reliable solution for mechanical and structural applications, with carbon content (0.12–0.25%) tailored for formability and strength. Seamless manufacturing ensures defect-free performance, ideal for automotive, machinery, and feed additive industries, where STKM12C and STKM13A pipes support heat exchangers and fluid lines, extending equipment life by 10–15%. The market, projected to reach USD 25 billion by 2032 at a 4.5% CAGR, reflects strong demand. Sustainable production and versatility enhance their appeal, despite competition from alloy steels. For inquiries or customized solutions, please contact us at [insert contact details]. JIS G 3445 STKM pipes remain a cornerstone for high-performance, affordable engineering solutions.

A312 TP316Ti stainless steel boiler pipes (UNS S31635, W.Nr 1.4571) are critical for applications requiring corrosion resistance and high-temperature performance, offering excellent resistance to intergranular corrosion, pitting, and oxidation up to 1600°F (871°C).

Galvanized steel hollow sections, made from materials like Gr.A, Gr.B, Gr.C, S275J0H, S355JR, S355J0H, S355J2H, A36, SS400, Q195, Q235, and Q345, adhere to standards such as ASTM A500, ASTM A53, API 5L, BS1387, EN39, JIS 3466, EN10219, and GB/T 13793-1992. The choice between hot-dip and cold galvanizing, seamless or welded forming, and specific shapes (round, rectangular, square) depends on application requirements. Rigorous quality inspection ensures compliance with mechanical and corrosion resistance standards, making these products reliable for diverse uses.

Headquarters

We are everywhere